Cost-effective layout and construction

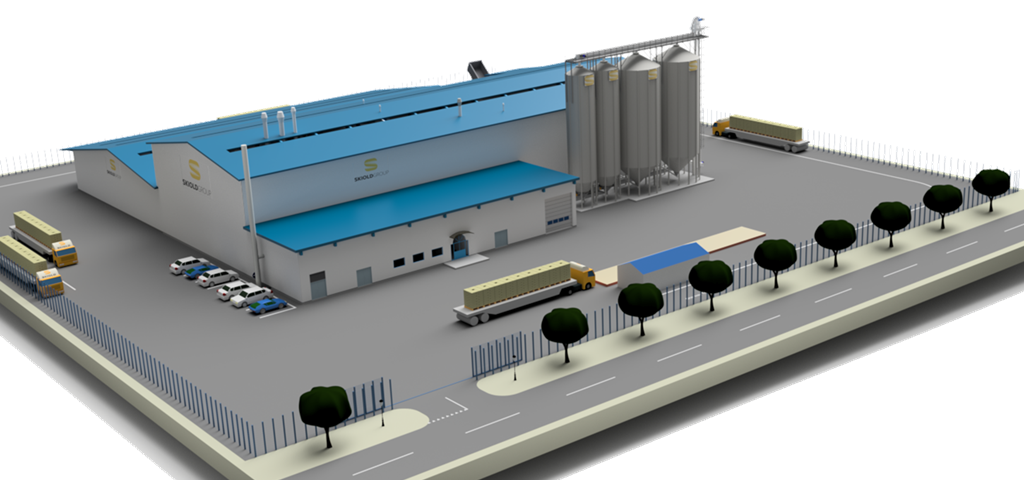

An aquaculture feed extrusion plant from SKIOLD is a module based construction and a large part of the construction will be based on off-site production, therefore a SKIOLD Aquaculture feed processing plant is quick and easy to build. The layout is cost-effective and the plant constructed in a one-level building that can be sourced from local contractors.

Horizontal design for improved performance

Contrary to similar solutions, the SKIOLD concept is based on a horizontal, on-the-ground construction. The one-level plant design yields a range benefits that optimise plant performance and ensure operational reliability. Primarily, the horizontal design ensures easy access to all points of operation, increases the efficiency of daily operations, makes it easier to establish a logic product flow, improves working conditions and ensures a safer work environment.

Easy-to-build solution

The horizontal plant design also offers a financial advantage as one-level constructions are less expensive to build compared to complex, multiple-level tower constructions. Furthermore, the modularised SKIOLD concept offers reduced construction time and a relatively uncomplicated building process which ensures that the construction project can be managed by local civil contractors. In combination, the modular concept and the one-level plant design also ensure an agile and flexible production that can easily be upgraded or adjusted to meet changing or growing market demands.

The benefits are:

- Easy-to-build solution

- Reduced construction time

- Can be built by local contractors

- Superior flexibility & scalability

- Easy to operate, upgrade and maintain

- Better workflow & easy access to the entire plant

- Safer work environment

- Improved employee retention

- Superior performance & efficient production

- Consistent feed quality & full traceability

SKIOLD aquaculture feed processing plants are batching plants, usually 1 tons per batch normally with 5-10 batches/h. With a 1 tons batch system, the capacity will be 10 t/h with 10 batches/h.

English

English

Danish

Danish

French

French

Swedish

Swedish

Vietnamese

Vietnamese

Spanish

Spanish

German

German

English

English