SKIOLD & Hanh Phuc Rice Jsc. have signed a contract

for the largest paddy rice handling and storage facility in Vietnam

Danish-based SKIOLD & Hanh Phuc Rice Jsc. have signed a contract for the construction of the largest paddy rice handling and storage facility ever built in Vietnam. Hanh Phuc Rice Jsc is a subsidiary of Tan Long, the largest distributor of livestock feed ingredients and a major exporter of rice and livestock in Vietnam.

Food waste is a global challenge and FAO estimates one-third of food produced for human consumption is lost or wasted. Rice is an important staple food and livelihood for many farmers in Vietnam, and the waste in rice production is estimated to 10-37 % deriving mostly from inefficient harvesting techniques and outdated storage and cooling facilities and the difficult climatic conditions and a difficult infrastructure.

Full-line, state-of-the-art handling and storage for the largest rice plant in Vietnam

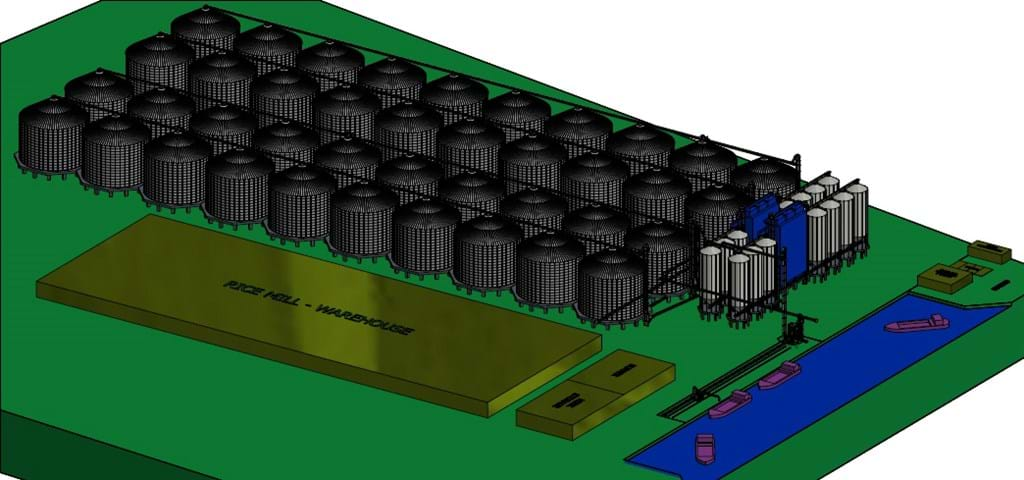

The new high-end paddy rice handling and storage facility will contribute to eliminating the waste of resources, as it will be updated, modern storage and drying solution focused on leaving a greener footprint. SKIOLD will supply the entire handling and storage facility including a batch unloader solution, cleaning solution, buffer silo with aeration, 40 storage silos (each 4,731m3) and conveying solutions for the facility. Annually, the factory will process 120,000 tons of rice, with optional expansion up to 240,000 tons of rice, making it the largest project for SKIOLD in Vietnam and also the largest rice plant ever constructed in Vietnam.

Lower CO2 emission and better food quality due to the proximity between harvest and handling

The plant will be located in the southern provinces of Dong Thap and Can Tho where rice is traditionally grown at large scale. Choosing to locate the handling plant closer to the rice farms means that less time is spent from harvest to handling which, firstly, has a positive effect on the quality of the rice and, secondly, has a positive impact on Co2 emission due to the shorter transport from field to the facility.

From field to food – fueled partly by recycled paddy husks

The SKIOLD Damas Omega cleans the rice and efficiently removes straw, leaves, soil, and other non-paddy materials from the rice. Within the next 24 hours, the paddy is dried to 14 percentage in the drying plant. The drying of the paddy within the first 24 hours after harvest is of utmost importance. The quick-drying process leaves the rice in the highest quality as it eliminates microbial growth, insects and mycotoxins. The SKIOLD equipment ensures a greener fuel consumption, as paddy husks are recycled as fuel for the plant. The dried high-quality rice is stored in large silos. The project is huge; not only is it a bare-field project, but it also involves the construction of a harbour for the many boats transporting paddy to the plant.

“This project is the largest rice plant we have ever made and one of the largest single orders in Asia. Asia is one of our most interesting markets and especially Vietnam has proven to be an important market for us. We have strategically chosen to make Vietnam the cornerstone in our growth strategy for Asia”, says Mr Lasse Viegand Hansen, CEO of SKIOLD A/S.

“We have just signed a strategic partnership agreement with Tan Long group, and we look forward to building this state-of-the-art paddy rice factory“, Mr Hansen ends.

Contact us for more information

English

English

Danish

Danish

French

French

Swedish

Swedish

Vietnamese

Vietnamese

Spanish

Spanish

German

German

English

English