Cleaning of cereals at DLG Seed in Hoerning, Denmark

About higher efficiency and better working environment

During the early summer, SKIOLD SEED department has optimized and upgraded the DLG Hørning seed treatment plant with both increased capacity, higher efficiency and a better working environment as benefit for DLG::

The DLG seed plant in Hoerning produces mainly seeds for hybrid rye, wheat, barley, and oats. The plant consists besides the two new Omega 181 IRE cleaners and the new Sigma 1004 cleaner also of indented cylinders, a table separator and a color sorter delivered by SKIOLD SEED.

The main task in Hoerning was do extend the fine cleaning capacity of the 2 seed lines from approximately 2 x 10 t/h to 2 x 15 t/h (wheat) and to improve the working environment by a new aspiration system.

Sigma 1004

Omega 181 IRE

The increase of capacity was done on almost at the same foot print as the existing old machines. This is possible due to the high efficient Omega cereal cleaning technology giving up to 40 % higher capacity pr. m2 of screens.

At the same time the quality of the cereals to the fine cleaning line was increased by installing a Sigma pre-cleaner and in combination with the unique aspiration R-modul on the Omega, the result is less cleaning waste which will be a substantial part of the pay-back of the investment. The new filter system secured a good and healthy working environment.

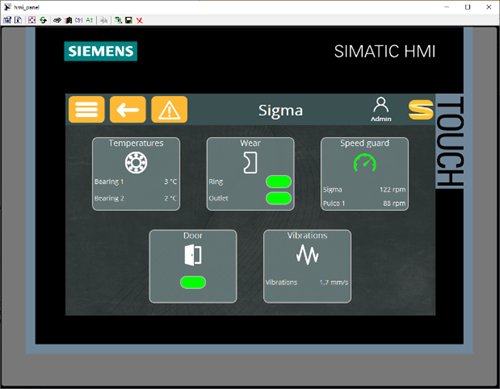

Both the Sigma and the Omega are equipped with the new SKIOLD Guard system that replaces the DamWatch system.

The SKIOLD Guard system introduces new features, e.g. vibration sensor, along with all the well known features of monitoring wear, break, speed and temperature to secure a smooth and optimal operation.

For further information please contact SKIOLD SEED / +45 2790 0082

English

English

Danish

Danish

French

French

Swedish

Swedish

Vietnamese

Vietnamese

Spanish

Spanish

German

German

English

English