PM motors for ventilation

SKIOLD PM motor has an energy saving of up to 70%

We have conducted an extensive test at one of our customers' plant, where we installed a PM motor in one of the exhaustions, which was continuously adjustable. A Triac regulated motor was also installed as well as a ventilator. Triac regulated means that the motor regulates via a voltage between 90 volt and up to 220 volt. The PM motor is set to 230 volt and is regulated via a 0-10 vdc. voltage.

Electricity meters were placed on both motors. At 100% ventilation, the Triac motor used 380 watt per hour, and the PM motor used 250 watt per hour. The energy saving is especially obvious when the plant is regulated downwards, in some cases a saving of up to 70%. The larger the motor effect, the larger the saving will be.

At our customer's plant, we estimated the saving to be 190.000 watt per year if for example they replaced 70 of their old ventilators of different sizes with PM motors.

The new PM motor can be be built into any kind of ventilation type/brand.

Ventilation is a huge power guzzler in your pig farm

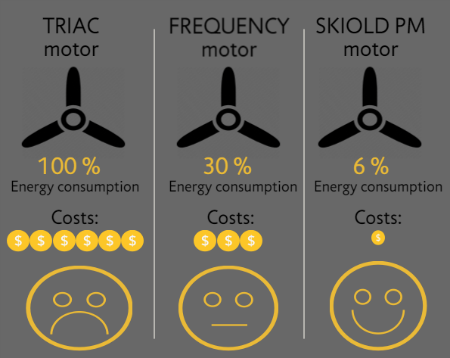

It makes perfect sense to optimize energy in order to reduce your heating bill. Ventilation, the largest power guzzler, consumes about 80% of the total power consumption in a pig farm. By choosing a SKIOLD PM motor you can reduce the energy consumption with up to 70% compared to a traditional Triac or Frequency motor. Several tests have been made to verify this result. Anneloev farm in Sweden and Hallumgade ApS in Denmark are some of the farms, which have obtained these results.

English

English

Danish

Danish

French

French

Swedish

Swedish

Vietnamese

Vietnamese

Spanish

Spanish

German

German

English

English