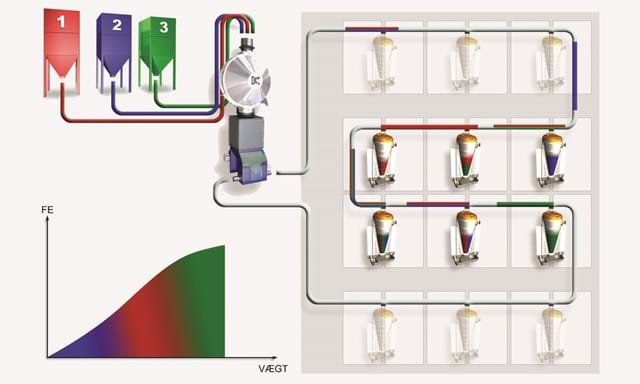

With SKIOLD Transport Multiphase feeding, a simple and accurate computerised feeding system, it is possible to control up to 2000 feed valves and 10 mixers onload cells. The equipment can control the grinding-mixing system, includ...

With SKIOLD Transport Multiphase feeding, a simple and accurate computerised feeding system, it is possible to control up to 2000 feed valves and 10 mixers on

load cells. The equipment can control the grinding-mixing system, including intelligent recipe-controlled grinding degree in connection with the SKIOLD disc mill.

The Transport multi-phase feeding system can handle up to 50 feed components in 40 silos. It is possible to feed your animals restrictively or ad lib, and efficiency reports on feed consumption are available at either pen or section level. Depending on the weight of the pigs, each pen is allocated exactly the mix that is most optimal at the given time.

MULTIFASE DRY - restrictive

The weight-controlled mixer prepares individual feed portions that are fed to the desired pen via the dry feeding system. The pipeline contains several portions at the same time, so time is optimally utilised. Pause times are encoded between the individual portions for the individual pens, which prevents mixing of portions for the different pens.

MULTIPHASE DRY - AD-LIB

A sensor is placed in each feeder to signal that the feeder is empty, so that only those feeders that are short of feed are mixed.

SKIOLD multiphase feeding can be operated from a PC with a multinational user menu, and it is possible to get efficiency reports at either pen or section level. It is possible to connect a mini-dispenser that can supply e.g. vitamins at valve level.

English

English

Danish

Danish

French

French

Swedish

Swedish

Vietnamese

Vietnamese

Spanish

Spanish

German

German

English

English