We wanted more precision. SKIOLD Liquid feeding was the solution

The animals have fresh, clean, healthy feed and they consume more

Patrick and Nicolas PERRAUDEAU, father and son, decided to renew their equipment to distribute liquid feed in their pig breeding unit. For this, they trusted the SKIOLD semi-liquid feeding solution.

Why did you invest in a liquid feeding system?

We have chosen to invest in semi-liquid feeding for corn and co-products. Today, we integrate 50 to 70% of co-products into the feed. Moreover, we are almost autonomous according to the year’s yields thanks to the co-products. If we went back to the original choice of liquid feed, we had wet corn, which was only usable fattening rations. Finally, we took a gamble on feed throughout the entire farm to have just one tool.

In 1993, we invested in a liquid feed distribution system, which was improved in 2000 (with multifarm software). 18 years have passed since then: The buildings have grown and so has the technology. Our equipment was getting old, we wanted more precision. We asked ourselves the question about renewing the local liquid feeding system entirely for two reasons:

- To start fresh for 30 years with the most efficient tool today.

- To be able to compare developments in this type of equipment with other suppliers.

It was also an opportunity to compare proposals with other suppliers.

Why did we choose SKIOLD?

SKIOLD has a local distribution network unlike other manufacturers where services are centralized. We needed field support for reparations on Sundays, with a service composed of several technicians, and organized on-call duty on weekends and holidays. This was the first thing to consider even before the price. What made our choice was the after-sales service: Here the follow-up is entrusted to the company AMR, represented by François REMIGERAUD.

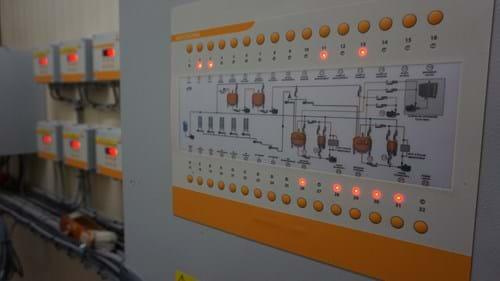

The second element of the SKIOLD choice lies in the software. The proposal of a software upgrade was part of our specifications: Ergonomics of the synoptic and connectivity between the PCs of the different sites. We wanted the software to be easy to understand. For us, the SKIOLD DistriWin software was by far the most user-friendly with its monitoring. Learning is very easy. Some of the other available software scared us with only numbers. In our choice, we took the people of the team into account, who work and will work with the tool.

The third element was that we were already used to the tool logic since the ML400. SKIOLD Distriwin has the same logic.

Finally, we had drawn up our specifications and the proposals from the manufacturers were very similar. But we remained faithful. We already have a on farm feed mill, ventilation, the old feed room from "SKIOLD".

Once SKIOLD was chosen as the service provider, we worked together to design the premises. We knew what we wanted and what we didn't want. We chose a completely separate location. The switch between the old and the new premises was done well, in two stages: First the preparation of feed and then finally the distribution.

Today, we are happy with the product. The offer lived up to our expectations.

What the system has brought us

Hygiene

In general, we have improved the hygiene conditions for the animals. This is an additional security for us. For fatteners, we went from 2.2% to 1.4% mortality. For sows, they eat better so we manage to ration them.

“ The animals have fresh, clean, healthy feed and they consume more.”

The system is designed so that the circuits are always clean before distribution. In addition, the feed never gets mixed thanks to two identical preparation and distribution blocks. Thus, the animal always has clean feed with clear water. Water disinfection with chlorine remains effective. We are seeing a big change in the palatability of the sows. They eat more and drink more.

On the pregnant part, I gave 1T/year and at the end of the year. It's subjective but I gained 10% feed/year/sow. This is not trivial.

Precision

In terms of feed distribution accuracy, it's night and day. The last control in November was 20 g in maternity, 100 g in fattening.

Indeed, the whole system is a good product with the drive that refines the distribution. This power inverter reduces the speed of the pump just before the end of the distribution, and all this without stopping. In addition, the valve makes it possible to recycle in case of too much pressure.

Tip: Check the weighing boxes every 6 months.

Software

On the SKIOLD DistriWin, here is what we use most on a daily basis:

- Schedules: To start immediately, to change the water in maternity, etc.

- The following parameters for sows: Rationing, valve modifications and water modulation. This is all very clear.

- Curves. They are simple to make.

- Consumption and handling history.

At just a glance, we have the consumption history. We notice any unwanted changes. What we particularly appreciate is the history of changes to remember manipulations and what other employees do. In any case, this indication is very useful, even for oneself. Jerome CHAPLAIN, Livestock Sales Director, points out that this is the first tool that is analyzed in order to identify the sources of malfunctions. It is an essential journal that allows you to be reactive in finding the solution.

- Work tables. They are also very practical. We can hide and make certain data invisible without it being deleted.

The software is intuitive. In the future, the smartphone application would be well received!

Any advice for breeders who would like to develop in liquid feeding?

In the completion of their project

Hygiene, precision and product homogeneity, these are the 3 elements to take into account:

- The water system must clean the pipes with a clean tank to improve hygiene.

- The mixture must be as homogeneous as possible from the beginning of distribution to the end of distribution.

- The pump with the drive is a crucial element to obtain the best possible accuracy.

Everyday life

At the beginning, two people were responsible for understanding the software and then explain to us how it worked. We are organized. Today, all employees use it, but only one person is in contact with the after-sales service for maintenance and updates. Nicolas is the only contact for the after-sales service. Indeed, he is following the breeding more and more, and will follow it even more in the future.

We only contact the SKIOLD after-sales service when we need them for the SKIOLD DistriWin software. When we use them, they have the knowledge and it is effective. Otherwise we call on our local AMR contact.

My final advice

Do not hesitate to invest if the budget allows it. It is an investment that quickly pays for itself in terms of performance and working comfort. Today, we have less waste and that's time saved!"

Installation by SKIOLD France dealer AMR, Beaurepaire

Do you want to know more? Contact us to learn more about our feeding systems for pigs:

CONTACT US FOR FURTHER INFORMATION

Farm information:

- GAEC La Vallée de la Vie, 480 sows, Maché - liquid feed

- Pig farmer - Horticulturist - Energy producer (methanization)

- 20 employees (mainly for horticulture) including 3 to 4 people for the pig production unit

- 300 Ha of cereals to feed animals

English

English

Danish

Danish

French

French

Swedish

Swedish

Vietnamese

Vietnamese

Spanish

Spanish

German

German

English

English